In SAP Business One, bin location refers to a specific and smallest unit within a warehouse where goods or materials are stored. They are typically organized hierarchically within the warehouse structure and are assigned specific attributes such as dimensions, capacity, and characteristics. Overall, storage bin locations are essential components of warehouse management within an ERP system, providing the foundation for efficient and accurate inventory management and warehouse operations.

Table of Contents

Importance of Bin Location Management

Bin locations allow for precise tracking of inventory within the warehouse.

By associating each item with a specific system bin location in SAP Business One, enterprises can accurately monitor the inventory level and item quantity, the storage location of every item, and the movement of orders in real time.

-

When goods are received, put away, picked, or replenished, SAP directs warehouse personnel to the appropriate bin locations, optimizing their workflow and minimizing travel time within the warehouse.

-

Storing bin locations in SAP enables organizations to optimize space utilization within the warehouse.

-

Bin locations are crucial for order fulfilment processes such as picking and packing. SAP determines the most efficient routes for warehouse operators to navigate through the warehouse and pick items from designated bin locations.

-

Bin locations in SAP Business One can be configured to adhere to regulatory requirements and safety standards.

Essential Aspects of Bin Location Management

Efficiently managing bin locations is crucial for optimizing warehouse operations in SAP Business One. Here are some key aspects involved:

- Bin Location Code Management: Automating the assignment of bin location codes ensures accurate inventory tracking and retrieval, reducing errors.

- Bin Location Master Data: Maintaining detailed bin location master data, including dimensions and capacity, aids in effective warehouse management.

- Receiving Bin Location Checkbox: The receiving bin locations feature helps identify which bin locations are being used as temporary storage bin locations for incoming goods.

- Warehouse’s Default Bin Location: Utilizing the warehouse’s default bin location settings optimizes storage space and improves workflow.

- Create Bin Locations: Automating the creation of bin locations based on warehouse layout reduces manual effort and increases accuracy.

- Inventory Transfer Process: Streamlining inventory transfers by automating bin location code updates ensures correct item placement and minimizes discrepancies.

- Item Group Categorization: Categorizing items by item group ensures optimal storage and enhances warehouse organization.

How to Store and Manage Bin Location

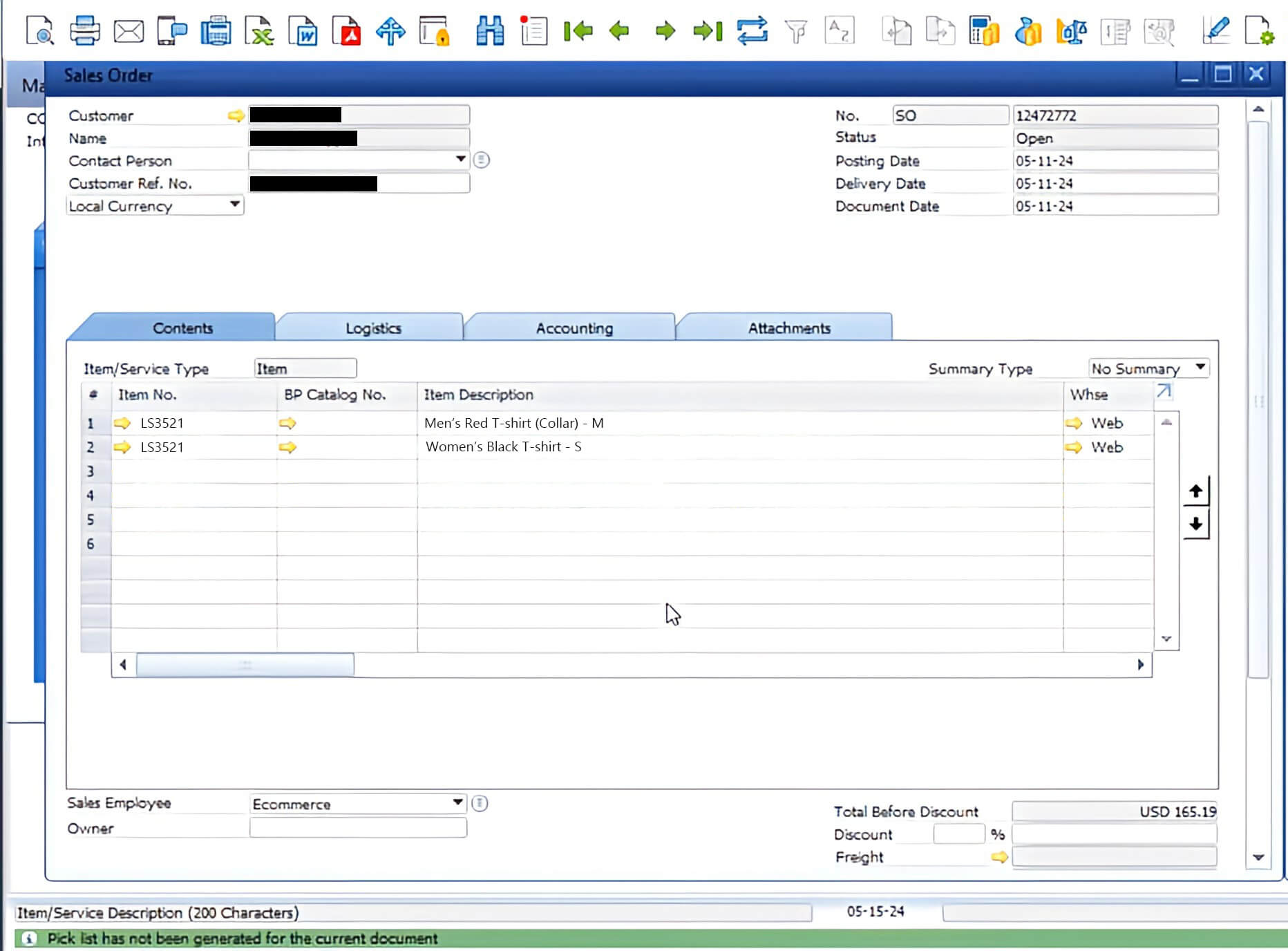

Every time an order is placed in SAP Business One, a pick list is generated for it based on the order information stored in the ERP. Bin locations are typically stored in the system as part of the warehouse management data. SAP’s Warehouse Management (WM) or Extended Warehouse Management (EWM) module contains the data related to bin locations within the warehouse.

SAP assigns a default bin location to each item on the pick list based on various factors such as the inventory item characteristics, storage requirements, and availability in the warehouse. Depending on the configured picking strategy in SAP, the system determines the most efficient way to pick items for the order. Once the bin locations are determined for each item in the order, SAP generates a pick list that specifies the items to be chosen and their corresponding bin locations.

Once the order is created, the pick list stays in “Open Status” and when the item is picked up from the warehouse for delivery it reaches to the “Released Status”. When the delivery document is synced with the particular batch number, the pick list data is synced.

Challenges Faced in Managing Storage Bin Location

Most companies usually maintain their pick list within SAP Business One. But challenges arise for businesses having multiple bin locations for a single product.

SAP usually chooses a single default bin location for a specified product in the pick list. But if multiple bin locations are assigned for a specified product, and you must select a specific bin location for an order, it must be added manually to the pick list.

APPSeCONNECT’s Solution to Automate Bin Location in SAP

Manually entering bin locations for orders can be time-consuming and prone to errors. APPSeCONNECT addresses this challenge by automating the process of analyzing and selecting the best possible bin location for each order.

By leveraging advanced algorithms and data integration, we ensure that the most suitable bin location is automatically identified and added to the pick list based on the order detail entries on your eCommerce end. This automation not only saves time but also enhances accuracy and efficiency in warehouse operations, ultimately leading to improved customer satisfaction and streamlined order fulfilment processes.

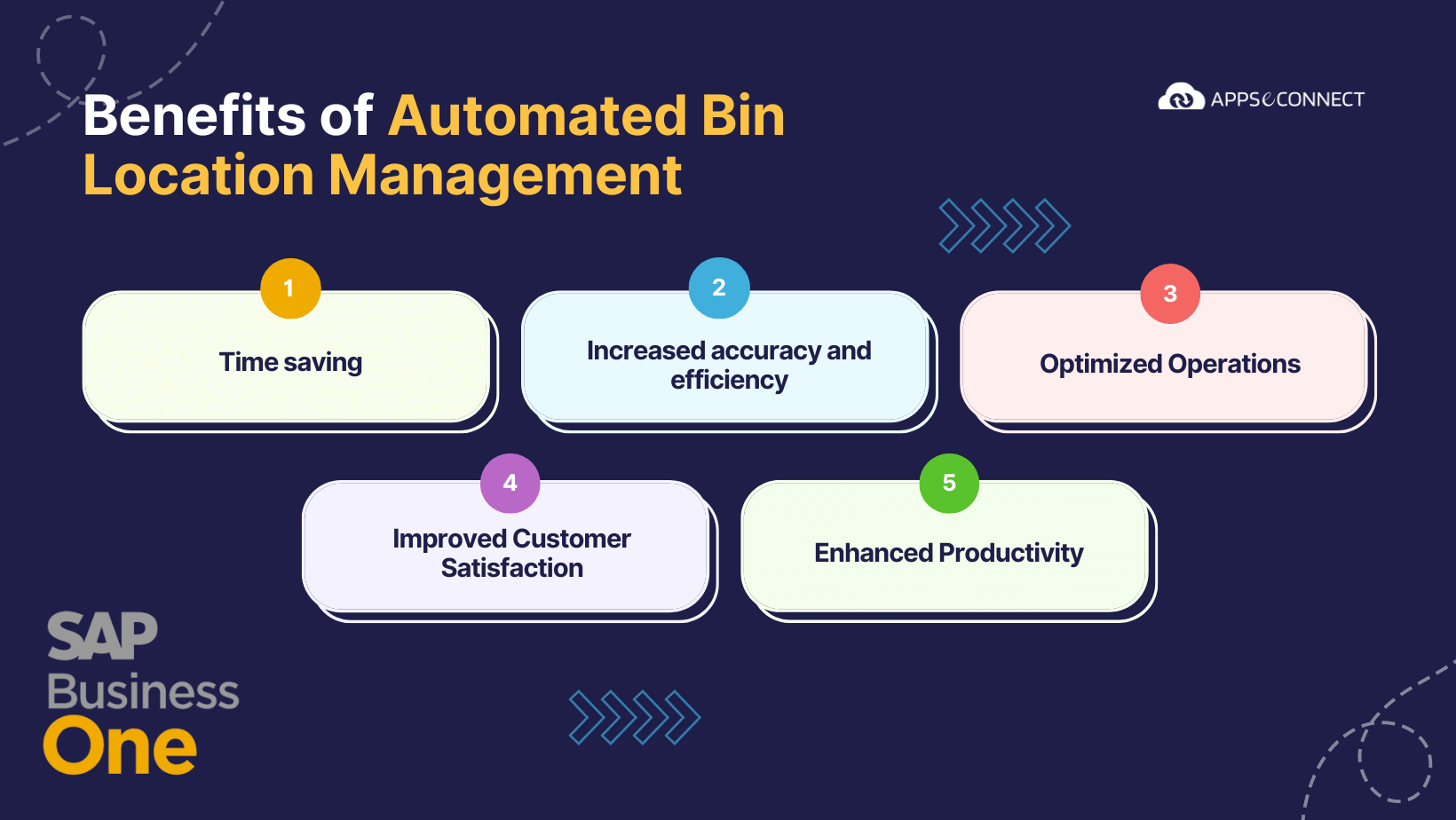

Benefits of APPSeCONNECT’s Automated Solution for Bin Locations

Time-saving

By automatically analyzing order specifics and selecting the best bin location, APPSeCONNECT eliminates the need for manual intervention and saves valuable hours for employees.

Increased Accuracy and Efficiency

Automated selection of the most suitable bin location removes the possibility of errors that could arise from manual data entry.

Optimized Operations

With APPSeCONNECT, users can ensure that orders are fulfilled efficiently and accurately. By automatically choosing the best bin location based on factors like item characteristics, storage conditions, and order priorities, our solution helps optimize warehouse operations and streamline order fulfillment processes.

Improved Customer Satisfaction

Timely and accurate order fulfilment is crucial for customer satisfaction. By automating the bin location function, we ensure that orders are processed quickly and accurately, leading to higher customer satisfaction levels.

Enhanced Productivity

By reducing the need for manual intervention in the bin location selection process, APPSeCONNECT frees up users to focus on other critical tasks. This leads to improved overall productivity within the warehouse or fulfillment center.

Applications Integrated with SAP Business One

APPSeCONNECT’s automated solution for bin location selection in SAP Business One has been developed to work in integration with two major eCommerce platforms – Shopify and Adobe Commerce (Magento).

So not only do we streamline the process of managing multiple bin locations, but we can also integrate your ERP system with these eCommerce platforms to create a comprehensive, automated business process.

Integrate SAP and Automate Bin Location With APPSeCONNECT

APPSeCONNECT is a leading business automation platform for SAP, and we specialize in a wide range of SAP Business One integrations, along with SAP S/4HANA connectors for larger enterprises. Our goal is not just to integrate applications, but to help businesses grow and scale seamlessly by leveraging the power of automation.

If you’re struggling with manually selecting and entering bin locations of specific items due to having multiple locations for the same item, our solution is made for you. Contact us to know more, and feel free to explore more about our low-code, intelligent integration platform. Whether it’s our highly advanced integration connectors or the trust of our existing customers who are succeeding with our integrations, we have proven our position as one of the best iPaaS and business automation platforms.

Click below to schedule a demo and try out APPSeCONNECT integration platform for your business.